Matt Keith came over to help with the bottom end disassembly, nothing too unexpected, except the cam bearings...

Splitting a type 4 case is pretty straight forward, Matt & I got right to it and didn't stop to take too many photos:

1) remove cylinders & pistons, the wrist pin on the most melted piston was not going to be removed, we had to remove the piston & connecting rod as a unit.

2) remove all the 8mm & 6mm case bolt/nuts & bottom sump cover, on type 4 motors I always suggest that newbies remove all the case bolts and when they are certain they got all of them to then go back and remove the last 2.

3) remove the oil pump, type 4 oil pumps have 2 tabs on the sides to get 2 large screwdrivers under to pry out, usually quite easy.

4) remove the nuts & washers from the 6 main case bolts, the bolts will remain with one case half.

5) to split the case I use a composite dead blow hammer, and just hit the loose half around the perimeter, after a few hits the case should begin to split, if not STOP! and look for any remaining bolts that may have been missed, do NOT pry the case halves apart with anything.

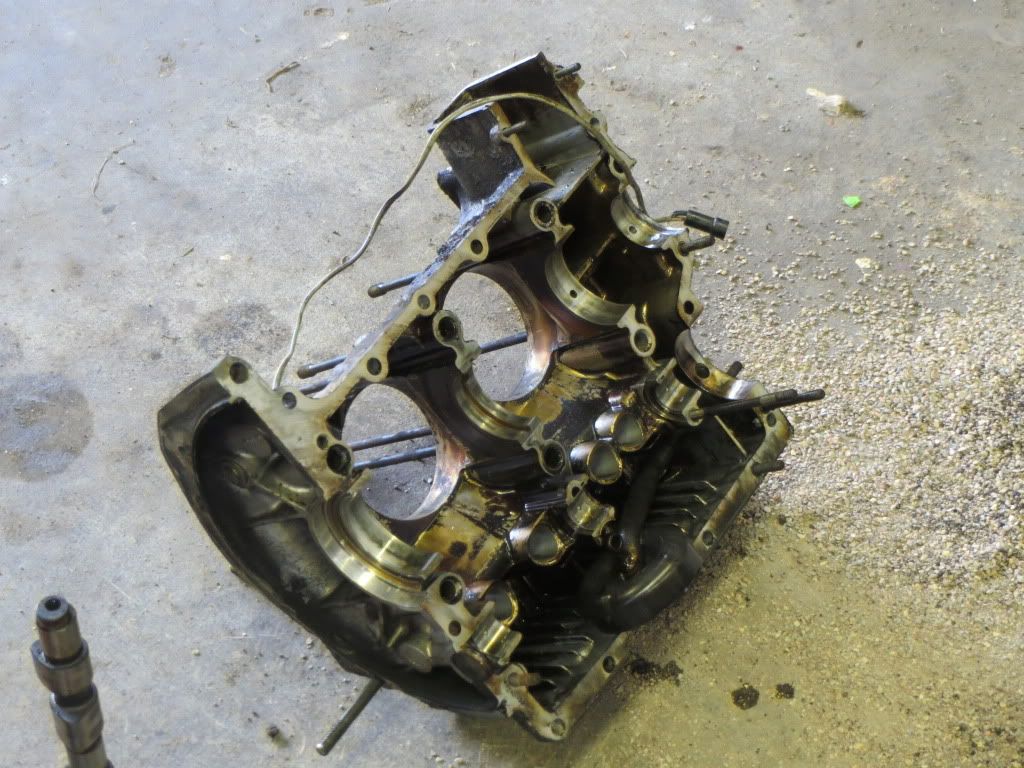

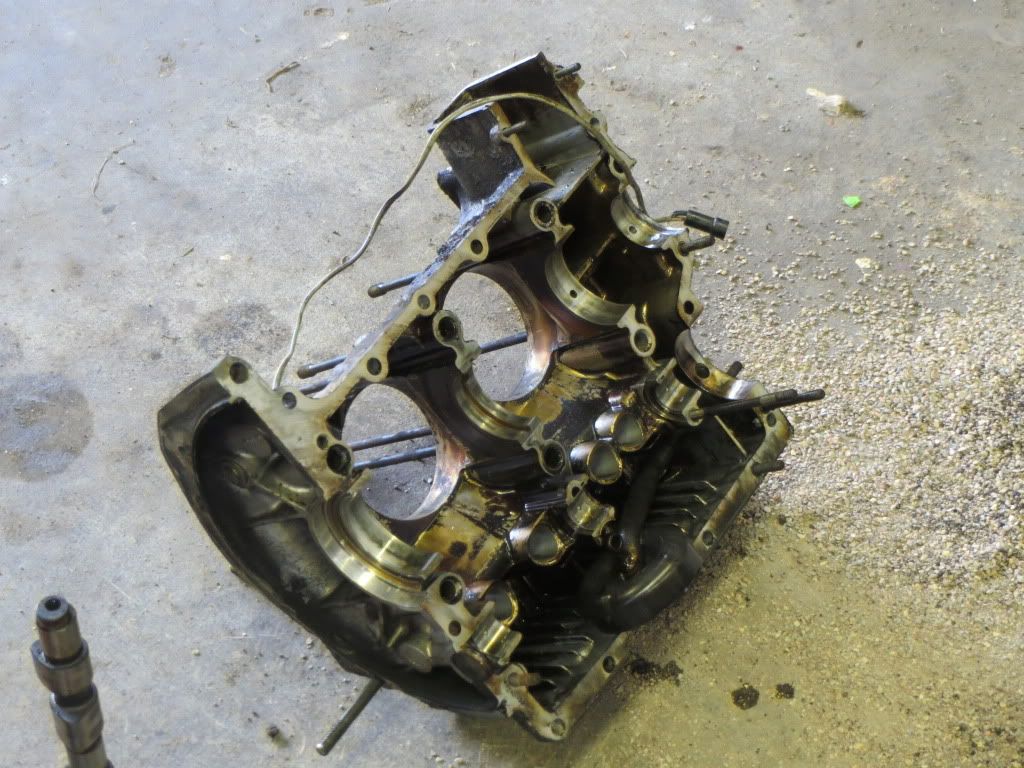

6) Once the case has been opened, the internals can be removed, make sure to remove the 5 main bearing pins and put them somewhere they won't get lost.

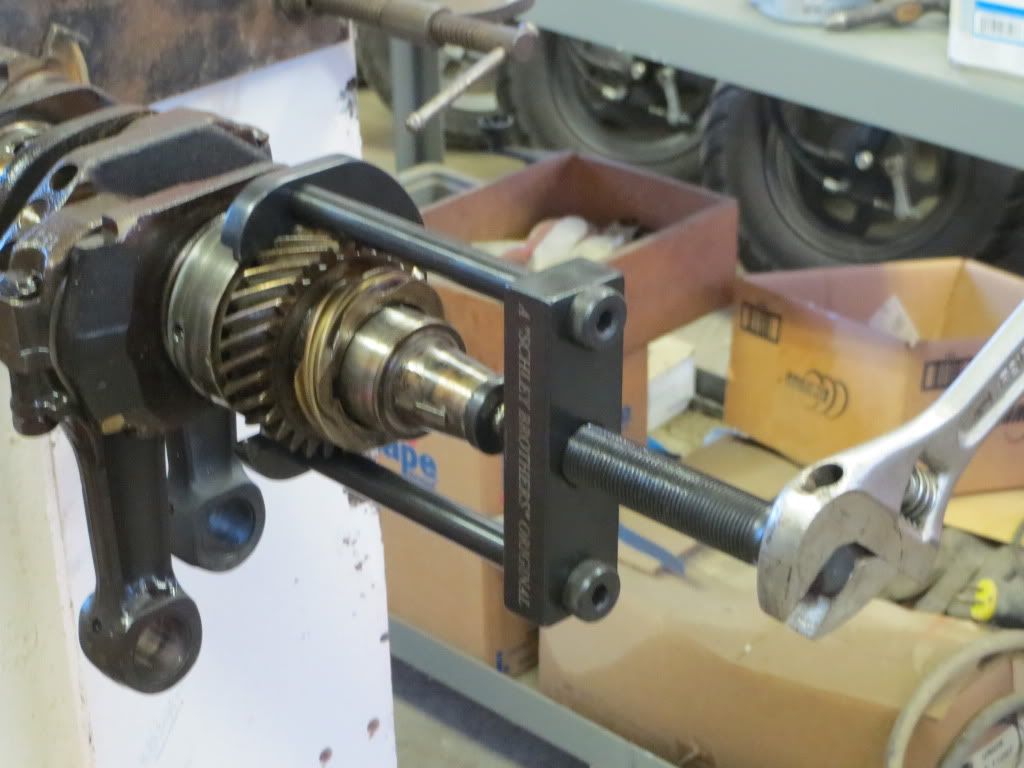

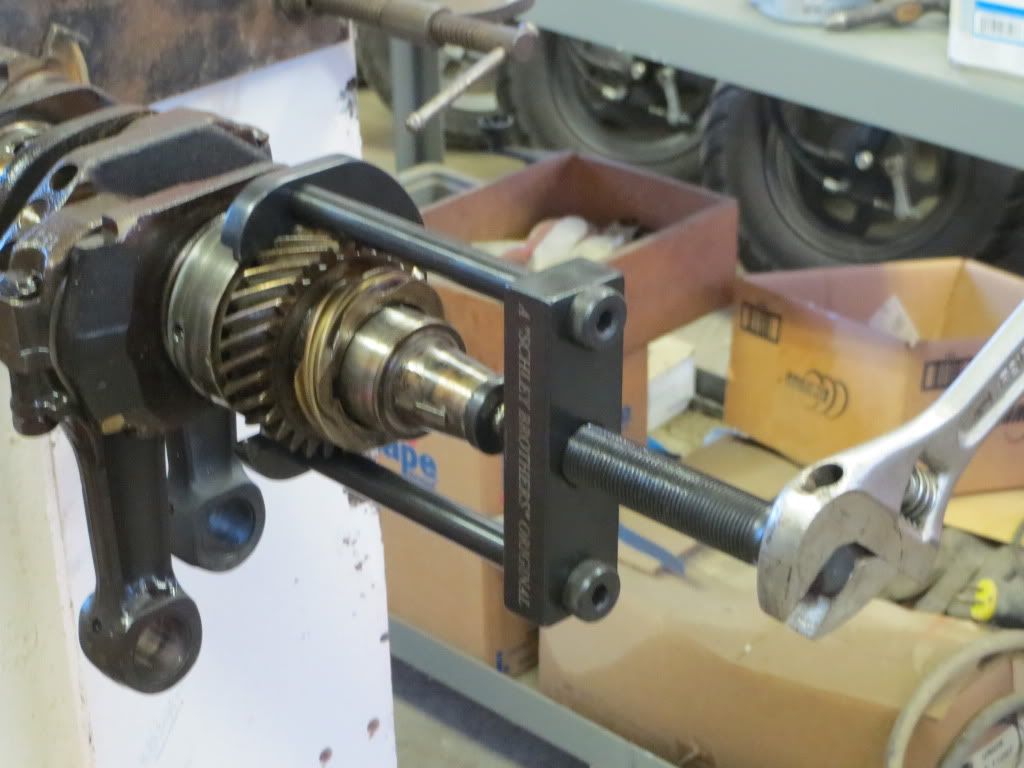

Crankshaft/ connecting rod disassembly requires a cam gear puller or some sort of press.

Broken part recap: oil cooler seals: outlet OK, inlet cooked to a crisp, hard, shrunk, discolored, leaking.

Piston, no explaination needed.

Cam bearings, melted & delaminating, this motor got very hot, more to follow....