Page 3 of 8

Re: 40 HP Refresh

Posted: Thu May 27, 2010 11:00 pm

by Howie

You GO, Tiger! IF you ever retire, you can open up a repair shop at home!

Re: 40 HP Refresh

Posted: Fri May 28, 2010 7:15 am

by toolbox

Six Volt wrote:

If Dale has time tomorrow he'll compress the rings. I don't know how to do that yet. Someday I hope to learn and get the tool you need. Hopefully I can start putting it together this weekend.

I found a Hazet ring compressor on eBay mislabeled as an adjustable oil filter wrench for $20!!!

Re: 40 HP Refresh

Posted: Fri May 28, 2010 8:10 am

by Six Volt

Awesome. I wish I was in Detroit!

I suppose I could look this up, but are rings compressed before or after the gaps on the three rings are set?

Re: 40 HP Refresh

Posted: Fri May 28, 2010 8:40 am

by Josh

You set the position of the ring gaps first, then compress and install/push them into the cylinders. Once they are in there, you cannot get to the rings. You are using new rings right?

Re: 40 HP Refresh

Posted: Fri May 28, 2010 12:53 pm

by Ken

Josh wrote:You set the position of the ring gaps first, then compress and install/push them into the cylinders.

Make sure you stagger the ring gaps so they don't line-up.

Re: 40 HP Refresh

Posted: Fri May 28, 2010 5:01 pm

by wwebner

also no ring gaps at the bottom.

Bill

Re: 40 HP Refresh

Posted: Fri May 28, 2010 7:59 pm

by Six Volt

Appreciate all that input. Yes Josh, new rings. Dale helped me get it covered. That means he did the rings for me and his method matched yours! Nevertheless, I learned a lot and know how it's done. Yes, it remains to be seen if I can really do it solo!

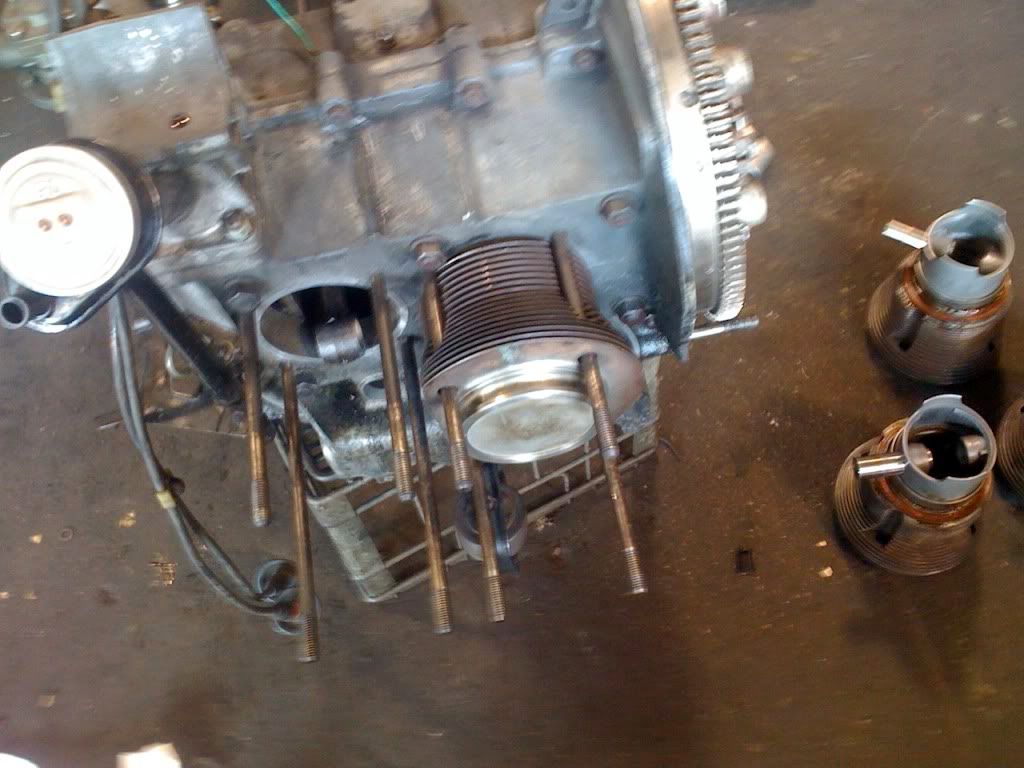

We did run into a few problems. Here's where it helps to have a knowledgeable veteran around when putting these things back together. In checking the rod bushings where the wrist pins connect the piston, Dale noticed the oil hole on the piston was blocked by the bushing. As a rookie, I would have missed this detail. Apparently the PO installed the busing wrong and blocked the hole.

Dale took care of it and fixed it. Amazing that the rod didn't seize from that oversight over the life of the motor! Crappy cell pics, but here you go.

Got the paper gaskets on the juggs with aviation permatex.

Had to mess with the studs that screwed out of the case but we got all four cylinders and pistons on...

Then we ran into our real problem. The pushrod tubes didn't fit. TOO BIG! That kind of ended the day. We were just getting ready to put the heads on and torque them down and clearly the pushrod tubes didn't fit. Too long. Oh well. That's life.

Just like with pulleys, there are pushrod tubes for 36 HP, others for 40 HP and still others for 1300-1600 motors. Such is life!

Dawn and I are off to the rib burn off. No engine for me this weekend!

Re: 40 HP Refresh

Posted: Fri May 28, 2010 9:26 pm

by Howie

Go eat some ribs and worry about it later.

Re: 40 HP Refresh

Posted: Sun May 30, 2010 8:34 am

by Ken

Howie wrote:You GO, Tiger! IF you ever retire, you can open up a repair shop at home!

You can move your shop over to Meister Rd. and I'll be your helper.

Re: 40 HP Refresh

Posted: Sun May 30, 2010 6:42 pm

by Six Volt

Ken wrote:Howie wrote:You GO, Tiger! IF you ever retire, you can open up a repair shop at home!

You can move your shop over to Meister Rd. and I'll be your helper.

One day with a veteran like Dale and my "newbieness" was very clear.

Most of you veterans have forgotten more in a week than I've learned in a lifetime. Nevertheless, learning about these old vw's is keeping me young!